Direct Dryers

Purge Vessel

Manufactured by Bepex International LLC, USA

The Bepex Hopper Dryer is incorporated into processes requiring near complete removal of volatile organic compounds (VOCs) from bulk solids. The Bepex Hopper Dryer provides a low cost option to bring VOC content down from 1-2% to ppm levels (i.e. – falling rate drying) by providing a small counter current flow of purge gas that provides the driving force.

Typical materials are those with an average particle size greater than or equal to 100 microns that require drying in the falling rate or diffusion limited zone. Before and after the drying process, the material may need to be heated, cooled, agglomerated, reacted or ground. Bepex offers a wide variety of process equipment and expertise to further add value to your process.

Fluid Bed Dryer

Manufactured by Bepex International LLC, USA

The Bepex Fluid Bed provides gentle handling in addition to efficient heat and mass transfer through direct contact of particles with fluidizing gas under controlled conditions.

The Process gas stream enters through the fluid bed air plenum passing through the gas distributor plate, which retains the solids above. Fluidization enables the product to flow continuously through the Fluid Bed, over flowing at the opposite end. Closed cycle Fluid Bed systems, in which inert gases can be recycled, are available to handle toxic products, oxygen sensitive products, or flammable solvent wetted materials.

PCX Dispersion Dryer

Manufactured by Bepex International LLC, USA

The Dispersion Dryer presents a compact and cost effective alternative to traditional Flash Dryers. It is ideally suited for applications where tight control of particle size and moisture is required, such as with pigments, pharmaceuticals and specialty chemicals.

Wet feed enters the hot air inlet of the dryer and immediately contacts the dispersion plates and the hot air. The action of the dispersion plates and liner increases the product surface area for rapid heat and mass transfer. Dried product passes through the classifier section and onto product collection. The resulting product is uniform and free of lumps. If required, some amount of size reduction is also possible.

Solidaire

Manufactured by Bepex International LLC, USA

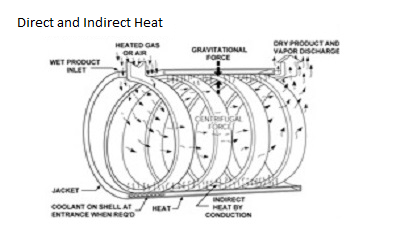

The Solidaire consists of a horizontal mechanical agitator rotating within a cylindrical housing. The housing is equipped with a heat transfer jacket which may be constructed for steam or liquid heat transfer media. Attached to the agitator are a large number of narrow, flat, adjustable-pitch paddles which sweep close to the inner surface of the cylindrical housing. Paddle arrangement and agitator tip speed combine to move material in a thin, annular spiral from inlet to discharge along the housing’s inner shell. This results in maximum heat transfer efficiency. The Solidaire can be operated in three modes: indirect heating, direct heating and combination of both modes.

TorusDisc

Manufactured by Bepex International LLC, USA

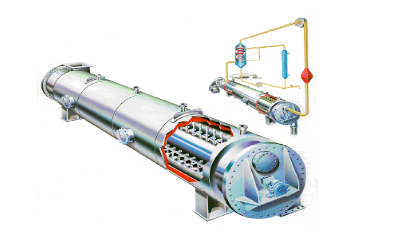

The TorusDisc processor consists of a stationary horizontal vessel containing a tubular rotor with vertically-mounted double-walled discs. These discs provide most of the total heating surface. Other heating surfaces are the rotor shaft and the inner wall of the jacketed vessel trough. Agitator plow or scraper bars can be added to increase exposure of new surfaces and prevent material build-up on surfaces. These design features allow the TorusDisc to achieve beat transmission coefficients two to six times greater than many other indirect dryers. Residence time ranges from minutes to several hours, making the TorusDisc more versatile than almost any other indirect heat exchanger available today.