Indirect Dryers

Solidaire

Manufactured by Bepex International LLC, USA

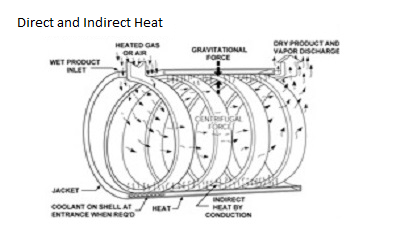

The Solidaire consists of a horizontal mechanical agitator rotating within a cylindrical housing. The housing is equipped with a heat transfer jacket which may be constructed for steam or liquid heat transfer media. Attached to the agitator are a large number of narrow, flat, adjustable-pitch paddles which sweep close to the inner surface of the cylindrical housing. Paddle arrangement and agitator tip speed combine to move material in a thin, annular spiral from inlet to discharge along the housing’s inner shell. This results in maximum heat transfer efficiency. The Solidaire can be operated in three modes: indirect heating, direct heating and combination of both modes.

TorusDisc

Manufactured by Bepex International LLC, USA

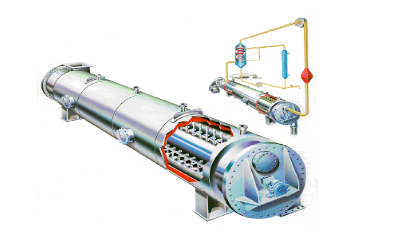

The TorusDisc processor consists of a stationary horizontal vessel containing a tubular rotor with vertically-mounted double-walled discs. These discs provide most of the total heating surface. Other heating surfaces are the rotor shaft and the inner wall of the jacketed vessel trough. Agitator plow or scraper bars can be added to increase exposure of new surfaces and prevent material build-up on surfaces. These design features allow the TorusDisc to achieve beat transmission coefficients two to six times greater than many other indirect dryers. Residence time ranges from minutes to several hours, making the TorusDisc more versatile than almost any other indirect heat exchanger available today.

Thermascrew

Manufactured by Bepex International LLC, USA

The Bepex Thermascrew is a modified screw-type conveyor offering significantly more heat transfer surface than other conveying devices. In either continuous or batch operation, it provides efficient and uniform heating, cooling, evaporating or other processing. Heat transfer media flows through both the rotor and body.

The product usually enters one end and moves by screw rotation to the discharge point at the other end. It is heated or cooled when it comes into contact with the hollow screw shaft and jacket surfaces, through which the heat transfer medium (HTM) flows. Screw rotation speed controls retention time and discharge temperature of the product. The tumbling action of the short pitch screw makes the heat exchange uniform and efficient.

Continuator

Manufactured by Bepex International LLC, USA

The Continuator employs an indirectly heated vessel with a slow speed rotor to maintain materials in a heated, agitated state for control of drying or thermal reaction. The design allows for processing a wide range of feed materials under controlled drying conditions. Mild agitation is provided by two distinct rotor types. Where back mix is required, a ribbon type rotor is used.

Slow speed operation minimizes particle breakage and short circuiting. This makes the Continuator ideal for longer retention time mass transfer limited drying. The continuator is used primarily for removal of tightly entrapped volatiles and for processes requiring longer retention time.